Acid-Treated Polymers Are Superior Stores for Drug Delivery

A new paper shows that a simple extra step could improve tiny polymers' ability to deliver drugs to the body.

Complete the form below to unlock access to ALL audio articles.

After the twists and turns of discovering a new drug molecule, pharma companies still face a mighty challenge: delivering their candidate drugs to the area of the body where they are needed.

Tiny sponges suck up drugs

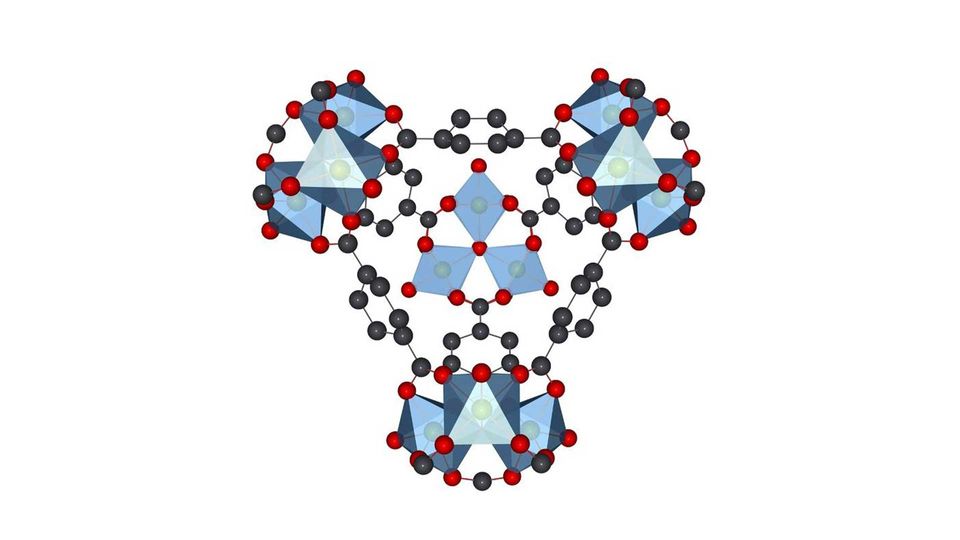

These molecules face a steeplechase of obstacles. Drugs can be metabolized out of our systems before reaching their target tissue; others need to be taken in vast quantities, making them unappealing to patients; others induce side effects that reduce patients’ quality of life. Enter nanoparticle-based treatments. These therapies utilize minute molecules, called metal organic frameworks (MOFs).

These molecules’ spongelike structures are studded with pores across their surface. They can be loaded with a drug of choice, which then is released over time through the pores. Current approaches to designing these molecules aim to maximize the drug volume they can be seeded with. A new paper shows that a simple extra step can significantly increase MOF drug capacity. The study was published in ACS Applied Bio Materials.

Researchers at the University of Miami, led by Dr. Fateme Rezaei, worked with a chromium-containing MOF called MIL-101(Cr). This MOF, synthesized from a mixture of chromium(III) nitrate nonahydrate, terephthalic acid, N,N-dimethylformamide (DMF) and methanol, has a cage-like structure with pores measuring 2.5 nanometers. By adding acetic acid – the same acid that gives vinegar its distinctive tang – the researchers created MIL-101(Cr)-P. This new MOF’s pores, at 5 nanometers, were double the size of those in MIL-101(Cr).

Accelerated release

The team next tested out how this expanded structure aided the MOF’s ability to load and release drugs. To do so, they used two test drugs – the nonsteroidal anti-inflammatory drug ibuprofen and the chemotherapy drug 5-fluorouracil.

Tests showed that the expanded MOF was able to hold more ibuprofen and 5-fluorouracil. Next, saline samples warmed to human body temperature to simulate the drug’s in vivo environment were dosed with MIL-101(Cr) and MIL-101(Cr)-P. Kinetic analysis showed that the modified MOF released both drugs more rapidly. While the ibuprofen was rapidly extracted from its nanocage soon after being added to the saline, the cancer drug’s release was delayed, which the authors say is because 5-fluorouracil required the MOF’s crystalline structure to be dissolved before release. This hints at the careful chemistry that has to be implemented to specialize delivery strategies for individual drugs.

Overall, the findings suggest that MIL-101(Cr)-P’s larger pores allow more drug cargo to be seeded into the molecule, while also allowing that same drug to be released more quickly. Future experiments will further explore how tweaking these microscopic cages can improve drug delivery strategies.

Reference: Pederneira N, Aina PO, Rownaghi AA, Rezaei F. Performance of MIL-101(Cr) and MIL-101(Cr)-pore expanded as drug carriers for ibuprofen and 5-fluorouracil delivery. ACS Appl Bio Mater. 2024. doi:10.1021/acsabm.3c01007